|

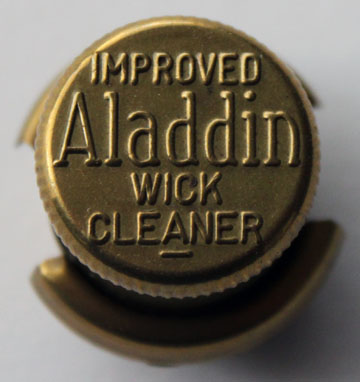

Aladdin started providing a wick cleaner with every lamp

sold from model 4 to the present day. Over the years

there have been at least 20 versions of the wick cleaner,

including at least 4 versions of the plastic wick cleaner. I do not have one of every Aladdin wick cleaner made, so those illustrated here represent a partial selection

The earliest wick cleaners were one piece and had three prongs

folded out from the wick cleaner's sides

The two skirt wick cleaners are a two piece construction.

There is a thimble shaped body with the bottom skirt held

in place by a friction fit and dimpling the assembled parts.

This means the positioning of the skirts in relation to the

lettering on the thimble part is not fixed and can vary during

assembly.

The earliest versions of the two skirt wick cleaner had a

straight bottom. The straight bottom two skirt versions are likely for model

9 through 11 lamps. The bottom of later versions were curved

inwards to prevent insertion damage to the wick. The Brazilian

model C wick cleaners (lowest on left) had the most pronounced

curve at the base.

Brass was rationed from 1942 to 1945. Wick cleaners made

during that time are of plated steel as was the wick cleaner provided with the steel Brazil model C burner. Aladdin was still selling model 12 burners in Australia during WWII. The model 12 wick cleaner provided with these burners were gray painted steel.

The first plastic wick cleaners were made in England, likely for the model 21 burner and were supplied with new lamps through 2013. A new brass wick cleaner was introduced in 2014.

IMPORTANT NOTE: In today's world of computer controlled precision machining, stamping and assembly it is easy to forget the metal wick cleaners were largely hand manipulated and assembled with not real thought of exact tolerances. All that really mattered was that the wick cleaner base fit into the top of the wick and that the skits or prongs that cleaned the wick were the same height. When I first started collecting wick cleaners I noticed that some of the same type were taller than others and assumed they were different versions. Then it occurred to me that it didn't make sense and I looked closer. Variations in height within a style occurs on the top part of a two part wick cleaner. The differences were how far the top part was pushed into the lower part before the dimples were applied to hold the two parts together. The height was not a specification that affects a wick cleaners fitness for use. My guess is that someone grabbed a bottom part from one bin, a top part from another bin, pushed them together and offered the assembly up to the machine that punched the dimples. I also have a couple cleaners in the same family that have slightly different length top sections. This too is not a function critical specification so I suspect the differences may be how the worker set up the cut off tool that day for the top part of the wick cleaner. It is the bottom part that is the most critical and I have not seen any variances within a family on the bottom part. I'm suggesting that height differences between members of a family are more a matter of differences in assembly and not changes in specification. unless you are comparing steel WWII wick cleaners to their brass equivalent. The slight height variations may be just a matter of how the worker was feeling the moment he pushed the two parts together. |

![]()

![]() Contents > Aladdin Wick

cleaners

Contents > Aladdin Wick

cleaners