Like many American incandescent mantle lamp companies in the US, Farmor was started by an individual with an idea and lots of tenacity. Most of the American mantle lamp companies started in the early 1900's buying a German made burner and coupling it to an American made lamp body. These went out of business at the beginning of WWI in Europe when German burners could no longer be imported.

Other entrepreneurs started with an idea to design their own burner and market it themselves, Most of these efforts were under funded and they never received the orders to stay in business very long. Inventors do not always make the best marketing people.

The Farmor lamp started out as an idea of a man turned inventor on a shoe string like many of the others. But where this entrepreneur differed is that he took his prototype to Sears and landed a large contract for lamps with enough funds to get the company immediately onto solvent grounds. Unfortunately for Farmor, they got a late start in the kerosene lamp business and 6 years after manufacturing started they were faced with war materials shortages and the rapid electrification of rural America.

Farmor company History:

The history of The Farmor lamp company is in its way the story of American spirit and perseverance during the 1930's great depression. It is the story of Bill Keller who lost his job as a time keeper when the factory he worked at closed down at the onset of the great depression. Who broke up wooden boxes to sell door to door as kindling. The idea of a kerosene lamp company started in 1930 when his wife asked why kerosene lamps put out a smoky yellow flame with not much light. It is the story of Bill Keller, initially unaware of kerosene mantle kerosene lamps and with only a high school education labored for 5 years to devise a bright kerosene mantle lamp. Of two people scraping to get by during those hard times, making sacrifices to get materials to build prototype burners. Of early prototypes built from available parts, often from the 5 and 10 store. Such as a cut down funnel for a burner cone. Bill was not a lighting engineer and the design was done by best guess, error and best guess yet again.

Bill Keller went to different companies until he found companies that would make wicks and mantles to his specification on speculation with no guarantee for an order for production quantities. When he finally developed a burner that worked dependably and met his expectations he applied for a patent and started building one off burners which he sold door to door. There still was not enough money to go into production. Bill wrote to Sears Roebuck & Co. telling them that he had a mantle lamp that reliably burned with 110 candle power asking for an order. Later he had a meeting with agents of Sears and demonstrated his burner. The agents measured the light output and satisfied themselves that the burner was indeed a reliable 110 candle power burner. When Bill Keller got on the train that evening to go home to St. Luis, he had a contract from Sears to provide them with 25,000 mantle lamps for 1935. So in 1935, the Farmor lamp company was born as also was Bill Keller Jr. the only child of the founder.

Bill Keller's development of the Farmor mantle lamp earned him an honorary induction into the Engineers Club of Missouri, with only a high school education. Up to that date only people with an engineering degree from a university were allowed to be members. He was presented with a lapel pin that he wore with pride until his death, and was buried wearing it.

In 1935 Sears took delivery of and sold 32,000 lamps. Bill started a burner manufacturing plant at 2862 Gravois Ave., St. Louis, MO. The chimneys and glass fonts came from a company called Dunbar Glass, located in West Virginia. The optional parchment shades were manufactured by a local company, Wallace Shade Co., St. Louis, MO. The wicks were manufactured by Secony Mobile. Early mantles were manufactured by Welsbach and later by Lindsay.

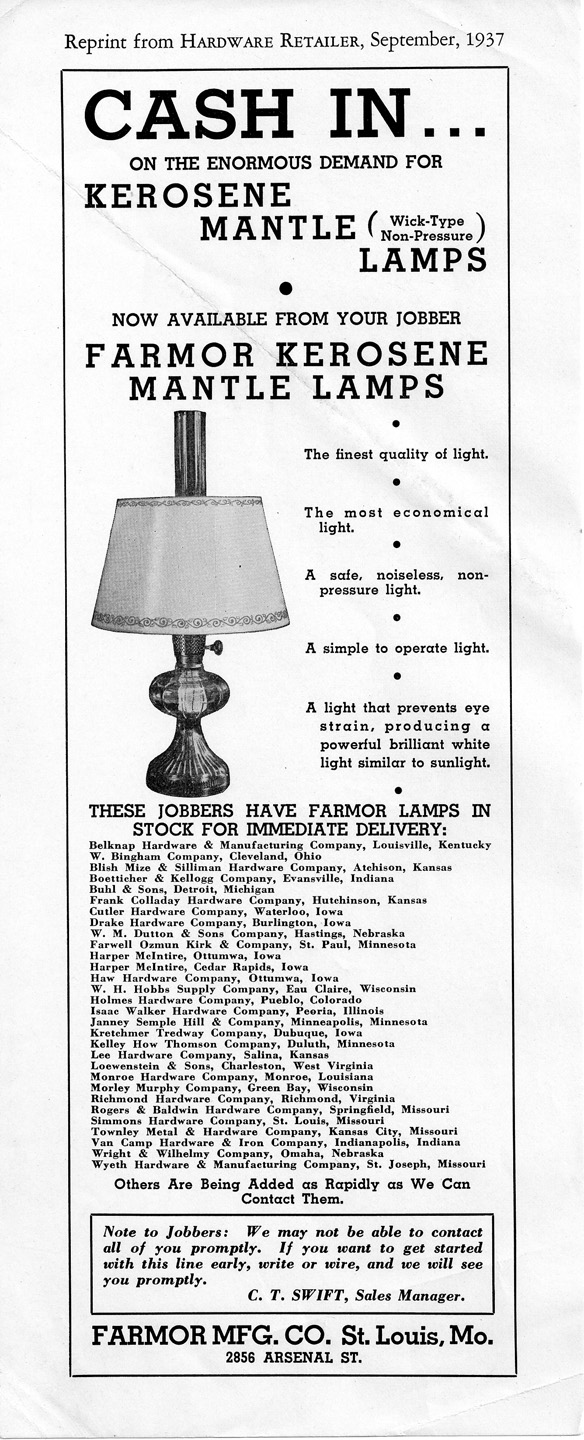

The company continued to grow from a single untrained inventor on a mission to develop a bright white light, to an initial order for 25,000 lamps to higher production quantities as additional distributors started selling Farmor lamps. Farmor lamps sold by Sears were marketed and sold under the name LIGHTMASTER. In addition to Sears he picked up a number of hardware store distributors such as Belknap Hdw., Louisville, KY, Orgill Bros., Memphis, TN, Janey, Simple, Hill Co., Minneapolis, MN, Witte Hardware, St. Louis, MO, Kruse Hardware, Cincinnati, OH. All except Orgill have since closed as the chain stores have overcome them. In the 1940's Farmor lamps were also offered through the Spiegel catalogue (1941-42?).

Farmor lamps were exported to Central and South American countries by the Hardware Distributors who also sold them to local hardware stores here in the U.S. The largest at the time was Belkanp Hardware of Louisville, KY, which had a very large export department and printed their catalogs in those native languages. The Farmor lamp company never directly exported as they were a small company. Some lamps were sold in Canada by the hardware distributors located in Minneapolis, Detroit, Cleveland and Seattle. Some distributors also exported some lamps and burners world wide. One unknown company, presumably in Australia, modified Farmor burners by adding a gallery lifting mechanism and changing the wick riser knob to a metal one with a winged Pegasus on the knob. I know nothing about the company.

The Secony Mobile Oil corporation created a Sun Flame Ltd. division to sell Farmor lamps in other parts of the world. The Sun Flame division sold lamps under different names into different countries. Some were marked as Sun Flame lamps. Lamps sold in Australia were labeled as Sunny model 505 lamps. These lamps were Farmor manufactured burners with specially labeled brass wick adjuster knobs and for some lamps specially labeled filler caps. The supplier of glass fonts for Farmor produced fonts from one of the Farmor molds in white glass for use on the mobile oil lamps.

At the end of World War II Secony Mobile Oil saw an opportunity to sell a large number of inexpensive kerosene lamps into China. They contracted Farmor to design and manufacture a very inexpensive kerosene flat wick lamp that could be produced in large numbers. The result was the "Fu Manchu" lamp which was a small flat wick metal lamp using an Eagle burner manufactured by Plume and Atwood. The Farmor lamp company sold more than one million of these "Fu Manchu" lamps between 1945 and 1948. During that time Farmor directly sold "Fu Manchu" lamps within the U. S. under the Farmor name as an emergency lamp. Production of the "Fu Manchu" lamps ceased when China went communist and the United States government halted export products made from brass and aluminum to China.

The Farmor lamp company grew steadily from its founding in 1935 until early 1942 when brass became a restricted strategic commodity. Farmor found it difficult to get brass to make burners until they received a government contract in 1944 from the U.S. War Department for 200 lamps to be sent to Oak Ridge, TN to be used in government built housing units. These were the housing units that housed people working on the A bomb. Farmor lamps manufactured during WWII had steel galleries and cone/baffle inserts.

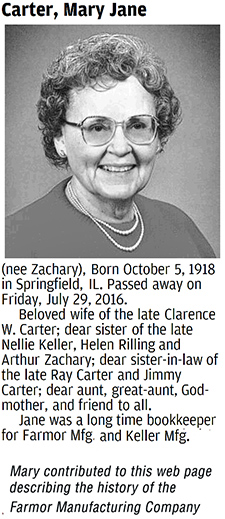

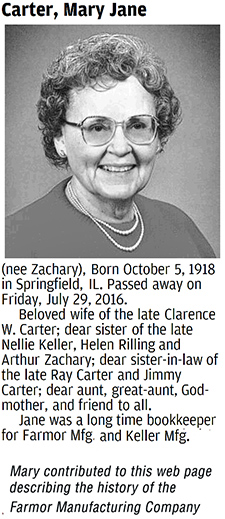

Since Farmor was having problems getting brass during World War II they started a division to make a "Victory Rake". With rationing of food throughout the US to help feed the troops, everyone was encouraged to plant a home garden for their own use. These were called "Victory gardens". Seeing a larger market in yard tools for victory gardens and later for the returning vets from WWII who purchased homes, the garden tools division grew. It sold garden tools under the name Gardex. The Farmor Manufacturing company was renamed the Keller manufacturing company overseeing a Farmor lamp division and a Gardex garden tools division. With the rapid post WWII electrification of rural America sales of kerosene lamps rapidly declined. By the end of the 1940's the Farmor lamp division of the Keller manufacturing company had ceased operations and all efforts were put into the growing Gardex garden tools division. They now have 4th Generation family members employed in the business. Keller Mfg./Gardex Co., 4324 Fyler Ave., St. Louis, MO 63116 www.gardexusa.com

A family affair:

1938 picture of the founder Bill Keller, his wife, Nellie Keller and son Bill Keller Jr. Bill Keller Jr. grew up to take over Keller manufacturing co. from his father. His son, James Keller is currently the president of the company and the fourth generation, Brett Keller, is vice president of manufacturing. Nellie's sister, Mary Jane Carter, was the company book keeper for the Farmor Manufacturing Co.

The histories of America's kerosene mantle lamp companies tend to be ephemeral in that a lot was never written down and no one saw the reason to keep what was written down beyond their immediate usefulness. Much of a company's history was tossed out when no longer needed in day to day commerce and never passed down from generation to generation. In the case of the Farmor Manufacturing Company I was fortunate that Bill Keller Jr. did not want to see the history of his family's company to get lost in time and reached out with information about the company and his father. Those of us who collect kerosene mantle lamps are fortunate in that we now have a more complete picture of the company and the man who started it all. Most of the time we only have old magazine advertisements and if lucky an old company brochure or catalogue that someone never got around to throwing out.

|

|

From Bill Keller Jr:

My Dad was known for his "thrift", to the point we would kid him that "why buy a work bench if you can work on the floor". He was only 4'10" and never weighed more than 115 lbs., but on the telephone he sounded 6'6" tall and he had the energy and drive of two men. He never appreciated our teasing him about his extreme thriftiness. Much of which came from his experiences of living during the great depression and starting both his business and a family on a shoestring.

My Dad's favorite hobby was visiting antique shops, and at one time he had a (non electric) lamp collection that numbered into the 20's. One of his that I have is a pull down hanging lamp with 35 Chech. crystal prisms. His prize was a double arm ceiling kerosene lamp (the type cowboys were shown in movies swinging on), which has a center container for kerosene supply, with two brass tube that ran from it to the actual lamps on each end. This lamp did not have mantels, simply a wick that burned for light.

One of his prized lamps was this whale oil lamp. The base is held on with hand made bolts and nuts. From what Dad learned, one would fill the rear opening with whale oil, and the front vertical cannons had either a wick type material, or simple cloth, or nothing and burned throughout the day and evening. It was used as a fire source to light cook stoves, fire places, etc. He had it appraised by a lamp expert (now deceased) who dated it as sometime in the 1500's and used in Scanda/North Sea countries (Norway, Sweden, Denmark, N Germany, Netherlands, etc.)

I remember vividly when we visited my Aunt Helen, (who along with her husband had a livestock and grain farm outside Waverly, IL), during the war years of the 1940's and had no electricity. As dark arrived she would light up maybe 7 to 10 of Dad's mantel lamps, and when we were ready to retire, a lamp would be carried to each of 5 bedrooms (she lived in a three story farm home with a veranda around 3 sides). When they arose before the crack of dawn to do chores, they would light the lamps and carry them down into the kitchen where a wood cook stove would be lit to make breakfast for the family and handymen. Occasionally when I flip the light switch today in my home, that memory pops into my head as a reminder of life in a simpler time.

|

This is the common black plastic wick adjusting knob found on Farmor burners. Plastic, being a thermal insulator, was used as a way to keep the wick adjuster knob from getting uncomfortably hot during operation.

When the Farmor black plastic wick adjusting knob breaks you end up with this hexagonal brass knob. If you see this you have a Farmor burner with a broken knob.

An uncommon plastic knob with donut pattern.

The burner on a Sun Flame lamp is a Farmor burner with a different wick adjuster knob. The patent number is a Farmor patent.

|

![]()

![]() Aladdin home pages > Other brands home page > > Farmor mantle lamps

Aladdin home pages > Other brands home page > > Farmor mantle lamps

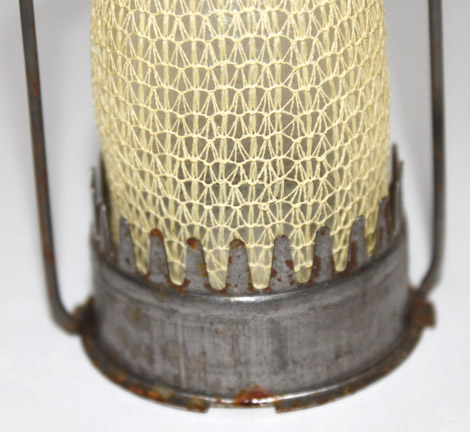

Late Farmor mantle with tab mounts mounted onto a burner

Late Farmor mantle with tab mounts mounted onto a burner