|

Aladdin Model 7 lamp Sold

from 7 August 1917 through July 1919

(Not sold into Canada. The model 6 continued to

be offered to the Canadian market)

401 shade |

416 shade |

|

The Aladdin model 7 lamp was a completely new and revolutionary

lamp in every sense of the word.

The model 6, propelled to fame by winning a gold medal at

the 1915 World's Fair in San Francisco, was extremely successful

for The Mantle Lamp Company. Popularity and sales were at

an all time high and The Mantle Lamp Company decided it was

time to design their own lamp from the ground up.

If you look back through Aladdin's previous lamp offerings

you can see that the Aladdin model 7 was the very first lamp

that was truly an all Aladdin lamp.

The models 1 and 2 were made almost completely from existing

Plume & Atwood lamp bowl tooling. Model 3 saw Aladdin's

first real engineering improvements. But they basically added

an improved wick adjusting mechanism, new gallery, mantle

and generator to an existing mix of Plume & Atwood tooling.

The models 4, 5 and 6 were basically marketing upgrades

with very minor actual improvements over the model 3. The

most noticeable change was the model 4 generator which is

a generic P&A style. The generic P&A style was more

robust and worked better with the Kone-Kap gallery.

There was some sort of licensing or ownership arrangement

between The Mantle Lamp Company and Plume & Atwood that

allowed P&A to use much of the Aladdin tooling to manufacture

lamps for other companies as well as Aladdin.

As an example the Solar lamp was in marketing competition

with the Mantle Lamp Company selling what is basically an

Aladdin model 1 quart and a half table font crowned by a Solar

labeled Aladdin model 6 burner. Because of this licensing

or lack of tooling ownership, Aladdin was basically in competition

with it's own lamps.

The model 7 tooling put an end to all that and for the first

time a uniquely Aladdin lamp was offered

.

400 shade |

|

Variations:

Table - Finish: clear

lacquer over satin finish brass

Font - (Wall mount & hanging,) - Finish: clear

lacquer over satin finish brass

Transition (very early lamps) - None I have identified

Accessories:

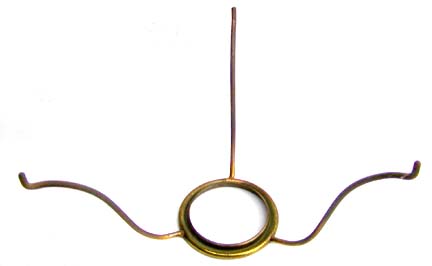

Bug screen: Early style bug screen

wick cleaner: 3 prong style, Aladdin name is underlined writing

Shade ring: An entirely new under burner shade ring. Satin

brass finish with arms spaced for 8-3/4" dia glass shade

Shades: table - 401, very rare 400 rose shade, hanging -

416

Chimney: Heelless globe type (rounded bulge near

base), crest logo

|

Click to see catalogue pages (15 pages + cover)

Undated but likely to be 1918 because first model 7 wall bracket had already been replaced by later cast open hoop model 7 & 8 wall bracket.

|

The Aladdin model 7 burner, like the rest of the lamp is completely

new in every sense of the word. If you look at each new feature

on the burner you can see how it was added to address what was likely

a common customer complaint. Not only was the model 7 going to be

different that the other P&A manufactured mantel lamps but is

was going to be very noticeably better. With the model 7, the Aladdin

sales force was going to have a real answer to the other company's

sales force when they said "It is exactly like an Aladdin,

only cheaper"

Inner wick tube

One very noticeable item that visibly separates the model 1 through

model 6 lamp bowls from the model 7 and later Aladdin centre draft bowls is

the inner wick tube. On earlier models the tube went from the bottom

of the lamp bowl to the top of the burner. This soft brass tube

stuck out above the top of the bowl a couple inches where it was

very susceptible to damage. The inner wick tube has to remain centered

in the burner and have no dents or creases in order for the lamp

to work correctly. Damage the tube when replacing a stuck generator,

or by accidentally dropping the lamp with the burner off and the

lamp will never burn right again unless you are skilled in brass

work. The Aladdin model 7 introduced a split inner wick tube with the top part attached inside the burner with 2 arms. This assured that the inner wick tube would be concentric with the outer wick tube and that the wick would be able to move more freely without the wick tubes pinching it on one side.

The new lower inner wick tube tapers to a smaller diameter at the

top and the new upper inner wick tube is firmly secured at its base.

This means the bowl's inner wick tube can get bent or otherwise

damaged and easily be made to fit to the burner. The side to side

gap between the between the two tubes lets air into the bowl to

equalize air pressure as the kerosene is drawn up into the wick.

Past solutions were vented filler caps or holes drilled into the

side of the inner wick tube.

Having a short top inner wick tube firmly affixed to the base of

the burner virtually assured that the inner and outer wick tubes

would remain concentric and allow easy wick movement. And if an

accident happened to the inner wick tube top edge, you replace the

burner and not the entire lamp.

This one change required several other changes to the burner. Suddenly

there were these two arms blocking the space between the inner and

outer wick tubes. Model 6 and earlier wicks were mounted from the

underside of the burner. The top inner tube support arms required

that the model 7 wick be mounted from the top.

|

The unreinforced wicks used at the time did not lend themselves

to customer mounting. The length of the wick above the the

holder is important to proper wick adjustment and the unreinforced

wick is quite fragile. Aladdin burner design requires the

wick gear to be inserted from below.

Aladdin's first attempt to solve this new dilemma was the

model 7 two piece wick carrier. You detach the gear from the

carrier then slide the mounted wick down from the top. Next

you fit the carrier gear to the burner gears, run it up to

the bottom of the carrier and lock it into place. There is

a gear lock on both sides of the wick carrier so you can never

insert the wick backwards.

You could consider the removable gear as Aladdin's first

wick holder that attaches to the wick carrier as does the

model 8 and early 9 holders did.

|

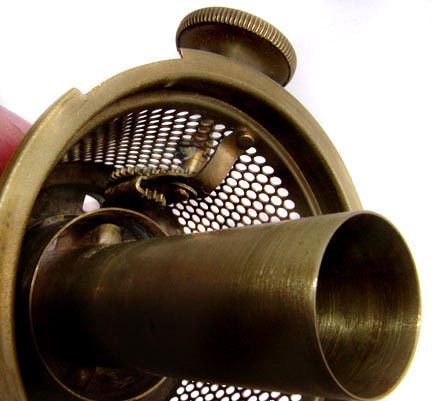

To insert the wick from the top you need a removable outer wick

tube.

Aladdin made the outer wick tube two piece with a removable top

section and permanently mounted the air distributor to the removable

outer wick tube. This provided physical space to get the bottom

wick ends through the base and to hold onto the wick carrier while

inserting the wick over the inner wick tube. It also allowed access

to the outside of the upper inner wick tube to keep it clean of

carbon deposits that can inhibit smooth wick movement. There is

a very short section of outer wick tube built into the burner base

that the bottom of the removable tube slides over.

|

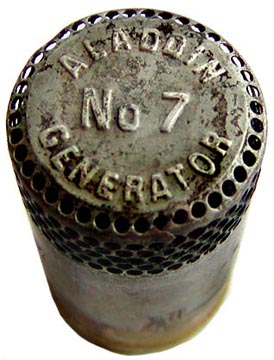

The new burner with removable wick tubes required a longer

generator. Aladdin still needed to produce model 6 generators

for the model 4 through 6 replacement parts market. So rather

than spending money for a second set of generator tooling

they added a brass skirt to the bottom of the generator created

by the existent tooling. The lettering on top of the generator

is formed by relatively inexpensive dies inserted into the

tooling.

It is quite conceivable that the same basic tooling was used

to form Aladdin and competitor's generators from model 4 through

11 with just lettering die changes. |

|

Another customer issue the Mantle Lamp Company addressed

in the design of the model 7 burner is the wick adjuster gearing.

The model 3 gearing, used through model 6, was a single gear

at the end of the adjuster shaft. Fine adjustment of the wick

needed to achieve the most possible light without sooting

was difficult. Also, if the wick or wick tubes were dirty,

turning the adjuster knob could be difficult.

The redesigned model 7 burner introduced gear reduction,

making fine adjustment easier and with less effort.

Of course all these additions took up space and the new burner

base had to be made with a larger diameter. Which, coincidentally

meant that if one wanted to take advantage of these new features

one had to purchase a new lamp and not just a burner. Also,

that Aladdin burners could not fit competitor's lamps. |

Model 7-8 gallery left & 9-11 gallery right |

The top of the new burner is

slightly larger in diameter than the previous burners and the

burner to gallery interlock is slightly larger and more robust.

This required a new gallery. Aladdin Galleries are two piece

with a single stamped bottom and tubular chimney attachment

section. The finger attachment ring is a friction fit over the

upper sides of the gallery base and is held into place by 3

evenly spaced dimples. Though the gallery base of model 3 through

6 galleries look the same as the base part of the model 7 through

11 galleries the dimensions of the newer gallery are slightly

larger. Generally by 0.1 inches or less in each dimension. |

|

The model 7 lamps got 3 entirely new glass shades and an entirely

new shade holder tripod. All tripods previously sold for Aladdin

table lamps had been mounted on the gallery. Lighting the lamp

required removing the shade then removing the gallery to put

a match to the wick. A shade attached to the base of the lamp

does not need to be removed in order to light the lamp.

Note the inner lip inside the ring. Under burner shade holders on pre-model 12 lamps have a vertical lip/ Under burner shade holders on models 12 and newer lamps have a horizontal inner lip. This is because of differences in the lamp base construction at the threads. The shade holders are not interchangeable. |

|

During the late nineteen tens, more Americans were living

in better homes with more and nicer furnishings. People were

getting rid of Victorian style furnishings and replacing it

with newer styles. Lots of Americans returned from the war

with tastes influenced by French designs and Nouveau styles

were big in America.

Aladdin jumped into the new furnishing styles market with

both feet when they designed the entirely new upscale and

fashionable model 7 product line. Aladdin paid for completely

new tooling for two new lamp bowls a new wall hanger and a

new lamp hanger. Tooling for the model 7 lamps could well

have been the single largest expenditure The Mantle Lamp Company

had made to date.

Both the hanging and table lamps have a 1-1/2 quart capacity. |

|

A new bottom skirt was made for this lamp. |

|

The bottom drip plate is in the same style as the one used

in the late model 6 font lamp except larger in diameter. |

|

An entirely new oil fill cap was produced for the lamp. |

The font hanger carried on the new style creating an integrated

up scale Nouveau look. The pull down extension for this lamp was

modified to go with the hanger. Two new wall holders were produced

for the new larger diameter font lamp.

The bolt used with the Model 7 ceiling extension.

|

The Aladdin model 7 got a whole new ceiling mount and extension. The body was brass plated cast iron. Nickel plated versions were available for the earlier lamps and the model 6 concurrently being sold in Canada. |

The model 7 and 8 font lamps were only available with the glass shade included. The Model 7 font lamp wall mounting bracket was originally a model 6 wall mount with the ring expanded to a 7 inch diameter. The steel 7 inch diameter ring held on to the arm with 2 rivets. The steel rim was stamped with the same pattern as the mounting ring on the hanging lamps. After release Aladdin quickly found out that the weight of the larger lamp full of kerosene plus the weight of the shade was too much for the wall bracket. The steel rim tended to bend down from the weight and people handling the lamp. So early on during model 7 production Aladdin introduced a cast bracket that was a lot stronger than the original. The cast wall mount is a lot more common than the early ring style wall bracket.

Early model 7 wall bracket. Note pattern on side of ring matches pattern on hanging lamp holder.

Late model 7 and model 8 wall mount bracket made of brass plated cast iron.

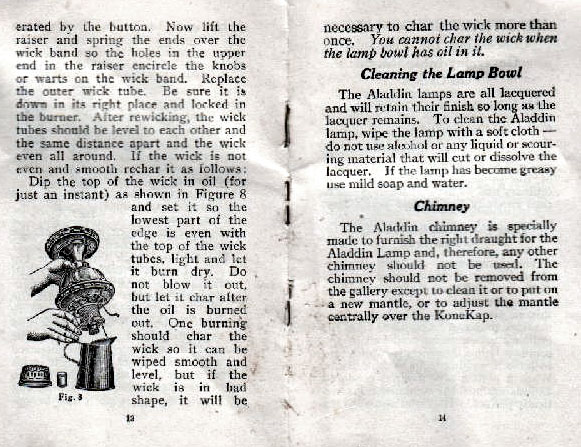

Finish

There seems to be a common belief that the Aladdin

model 7 and 8 lamps used a special finish that was different from

other Aladdin lamps and very fragile. I've heard it from most collectors

and dealers I have talked to since I first started collecting Aladdin

lamps. Of all the brass finish Aladdin lamps, people seem

willing to pay a higher premium for an original factory finish

on a 7 or 8 than for other early Aladdin brass lamps. I'm

told that this is because the finish is special. It

is time to bust this myth. The finish is just plain clear

lacquer applied over satin finish brass. Plume & Atwood has

been applying clear lacquer to brass finished lamps before Aladdin

was founded and continued to do so. To the best of my research

all Aladdin brass finish lamps ever made were finished with a clear lacquer

paint from model 1 up through model 23A. The finish on the

model 7 and 8 is no different from that of a model 5 or 6. The

only difference is that collectors are more careful with the finish

on model 7 & 8 than the other models.

In the Aladdin sales lists the finish is listed as

satin brass, same as the models 5 & 6 before them. Below

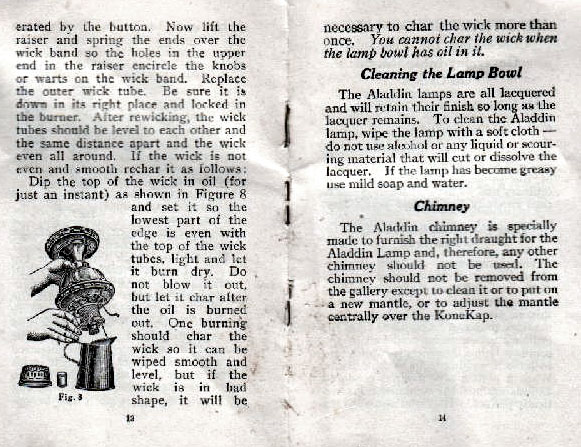

is a picture from a model 8 owners manual. I

typed the text below since readability isn't the best.

From the manual page above:

" Cleaning the lamp bowl

The Aladdin lamps are all lacquered

and will retain their finish so long as the lacquer remains. To clean the Aladdin

lamp use a soft cloth - do not use any alcohol or any lacquered

or scouring material that will cut or dissolve the lacquer. If

the lamp becomes greasy use mild soap and water."

These are the same instructions you will find in

the model 6, 5 and I presume earlier lamp manuals. There

is nothing special about the finish on the model 7 & 8 lamps. The

only thing special is the care taken by collectors and dealers

to preserve it. The

old formula lacquers had a golden tone to it which deepens with

age. The

lacquers used on Aladdin lamps for the last half century are

clear with not colour tone to it.

Parts support and interchangeability:

Mantles: Production of Aladdin KoneKap mantles ceased in 2007. In 2012 Aladdin introduced an adapter that fits onto a model 3 through 11 gallery that allows the use of a Lox-On mantle with the earlier lamps.

Wick/Carrier: Models 8, 9, 10 and 11 wicks can be used if you use the correct carrier for that wick. Model 11 wicks were discontinued in 1955.

Gallery: The model 8, 9, 10 and 11 galleries can be used.

Generator: Model 8, 9, 10, and 11 flame spreaders can be used. The model 11 flame spreader was discontinued in 1955.

Burner: Model 8, 9, 10, 11 and 12 burners can also be used with this lamp

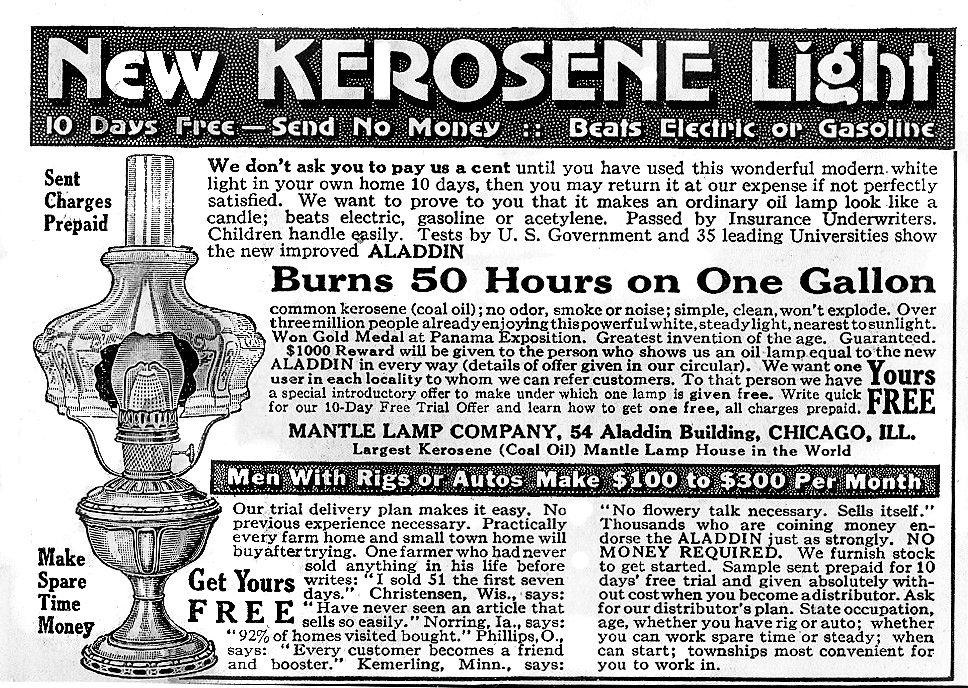

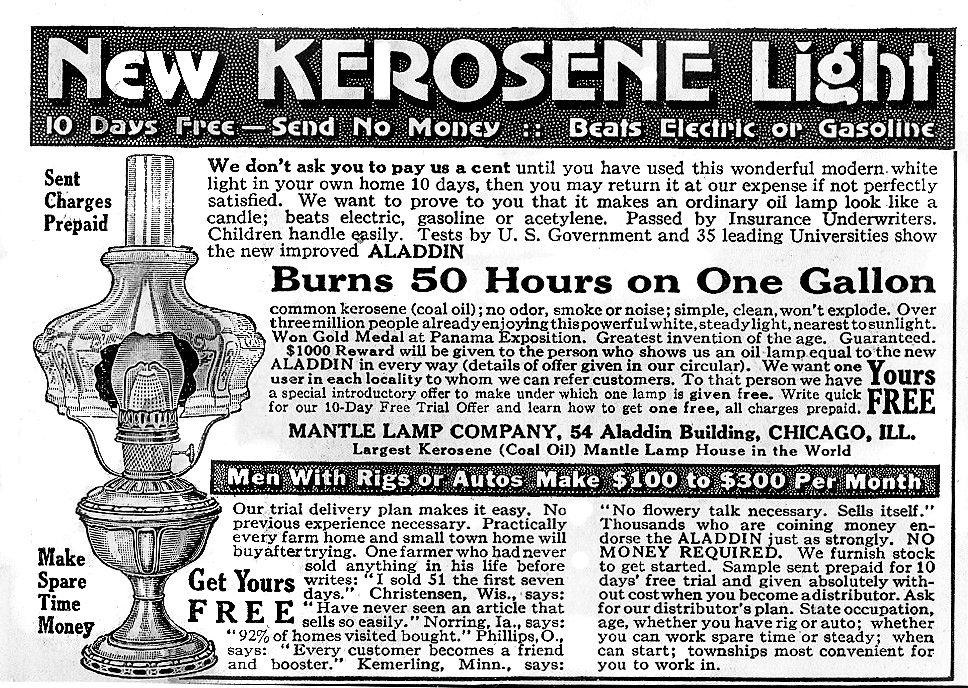

Click to see a high resolution pdf file of this Aladdin model 7 ad

|

![]()

![]() Contents > Aladdin model 7 lamp

Contents > Aladdin model 7 lamp